Sooner or later, every homebrewer needs to drill holes in sheet metal. The classical situation is drilling holes to mount switches, connectors and potentiometers on the front panel of some instrument. The problem is that the diameter of the hole is much larger than the thickness of the sheet and regular twisted drill bits do not work well. The usual result is a hole with a bizarre shape (definitively not round) and a rough edge.

Well, common twisted drill bits are designed to work in bulk and solid materials. If the thickness of the piece to drill is comparable (or larger) than the diameter of the hole, the drill bit is well guided and cuts a nice and circular hole. If the material is too thin, the tip will already drill though before being held in place by its own hole, the tip will vibrate (it's elastic!) and the hole will be rough.

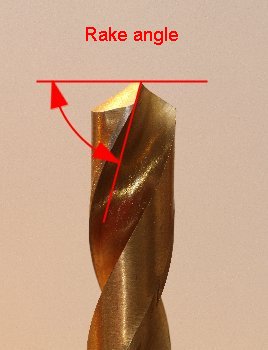

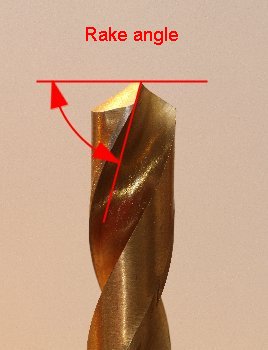

Furthermore, common metal drill bits have a rake angle around 60° (see picture above). This is the angle between the surface we want to drill and the traveling surface of the cutting edge. This angle "bites" into the material, cut the chips and pulls the tip forward making it difficult to control.

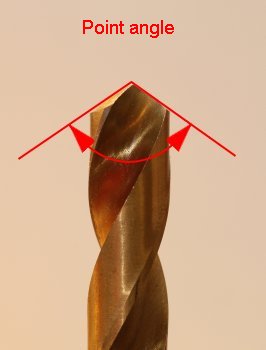

There are many solutions to this problem: some, like laser cutting or die cutting, are reserved to the industry. Punching holes is an easy and effective method, but one has to have a punch for every required diameter and shape, and punches are expensive. Special drill bits suitable for sheet metal exist but are difficult to find; the usually have a rake angle close to 90° and a point angle (figure below) also around 90° instead of the classic 118°.

People with good mechanical skills usually grind drill bits down to modify the rake angle; making it around 90° is usually enough for drilling nice round holes. This operation is not easy to do by hand if you aren't an expert. If done incorrectly the drill bit will cut larger diameter holes than what it's supposed to do. And still you need an extra set of drill bit to use only for sheet metal (ok, they are also good for drilling brass, copper and other soft metals).

The easiest and simplest solution is to drill through a cloth with a regular drill bit! No kidding, it really works.

Ok, let's go through step by step. First mark the center position of the hole and punch it in the surface, this will guide the drill bit at the beginning and prevent it from sliding sideways.

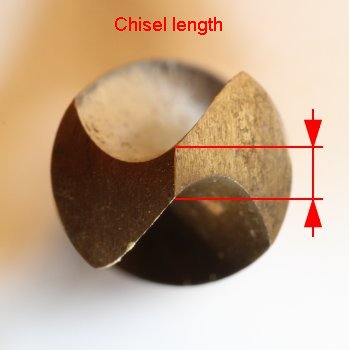

Than drill a smaller hole to guide the final drill bit. The diameter of this pilot hole should be slightly larger than the chisel length (picture below) of the final bit.

Since this is a small hole, a normal drill bit will work well in the sheet metal without extra precautions.

Now drill the final hole at the desired diameter with the corresponding twisted drill bit, but put a cloth between the bit and the metal. The pilot hole will help you positioning the drill bit, and than just drill as usual. The cloth prevents the drill bit to dig into the metal without the need of changing the rake angle. It's not as effective but much simpler.

A short movie showing this technique is also available.

Watch the movie: sheetmetaldrill.mp4

(2,068,328 bytes, 51 s, H264, 640 x 360, 24 fps).

A very simple technique to drill large holes in sheet metal has been presented. It consists in simply putting a cloth between the drill bit and the piece to drill. As shown in the picture belo, the result is not perfect but is so much better that it's definitely worth considering, since it's simple and doesn't require any extra tools or particular skills.

| Home | Mechanics | Page hits: 074771 | Created: 12.2012 | Last update: 12.2012 |